Blog

Precision steel pipe processing method

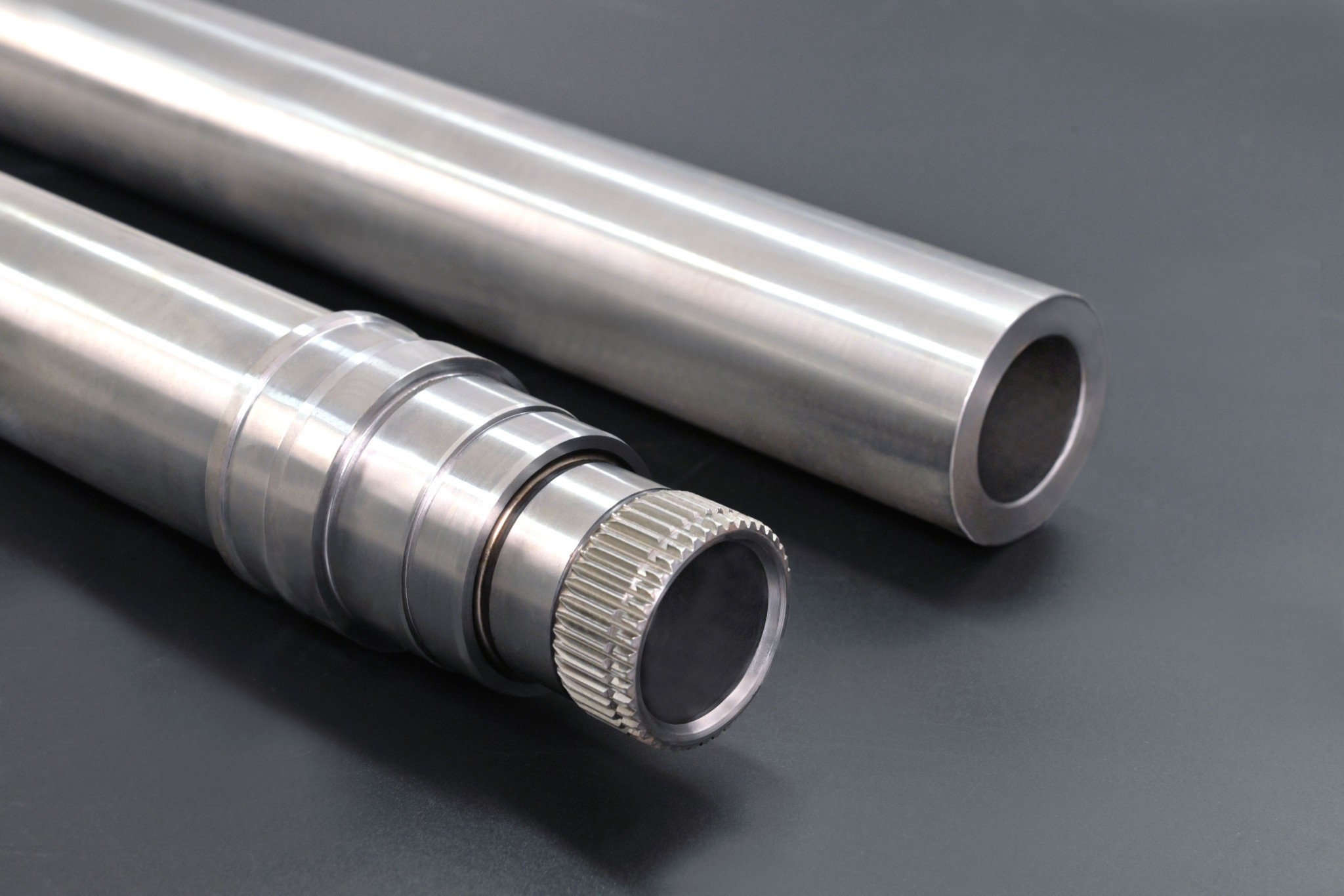

Summary:Precision steel pipe is a kind of high-precision and high-quality steel pipe product, which is widely used in aerospace, automobile manufacturing, mechanical processing and other fields. The processing method of precision steel pipe plays a key role in ensuring product quality and improving production efficiency. This article will introduce several common precision steel pipe processing methods.

1. Overview

Precision steel pipe is a kindHigh precision, high qualityThe steel pipe products are widely used in aerospace, automobile manufacturing, machining and other fields. The processing method of precision steel pipe plays a key role in ensuring product quality and improving production efficiency. This article will introduce several common precision steel pipe processing methods.

2.cold drawing method

Cold drawing method is a commonly used precision steel pipe processing method. The method uses a drawing machine to heat the hot-rolled steel pipe or seamless steel pipe to an appropriate temperature for drawing, and the diameter and wall thickness of the steel pipe are accurately controlled by cold drawing. The precision steel pipe processed by cold drawing method has smooth surface, precise size and excellent mechanical properties.

3.cold rolling method

Cold rolling is another common precision steel pipe processing method. The method uses a cold rolling mill to cold-press the hot-rolled steel pipe or seamless steel pipe, and the steel pipe is further sized and surface treated by rolling. The precision steel tube processed by the cold rolling method has a highly uniform wall thickness, good surface quality and precise dimensions.

4.hot rolling method

Hot rolling method is a kind of precision steel pipe processing method suitable for large diameter and large wall thickness. The method uses a hot rolling mill to heat the billet to an appropriate temperature for rolling, and the steel pipe is subjected to size control and surface treatment by rolling. The precision steel pipe processed by hot rolling method has high strength and toughness, and is suitable for the occasion of withstanding high pressure and high temperature.

5.cold drawing and cold rolling method

Cold drawing and cold rolling method is a kind of precision steel pipe processing method which makes comprehensive use of cold drawing and cold rolling methods. In this method, the cold drawing machine is used to control the size of the steel pipe, and then the cold rolling mill is used to further process the steel pipe to achieve higher accuracy requirements. Precision steel tubes processed by cold drawing and cold rolling have high dimensional accuracy and surface quality.

6.Internal and external core-pulling method

The internal and external core-pulling method is a special precision steel pipe processing method. The method uses a core-pulling machine to extract the inner core and the outer core at the same time, so as to obtain a precision steel pipe with uniform diameter and wall thickness. The precision steel pipe processed by internal and external core pulling method has extremely high dimensional accuracy and internal and external surface quality.

7. Summary

There are many processing methods for precision steel pipes, and different processing methods are suitable for different steel pipe sizes and requirements. Cold drawing method, cold rolling method, hot rolling method, cold drawing and cold rolling method and internal and external core pulling method are several common precision steel pipe processing methods. In practical applications, suitable processing methods should be selected according to specific requirements to ensure product quality and performance.

The above is a brief introduction to the processing method of precision steel pipe, hoping to be helpful to readers. In actual operation, it is also necessary to make reasonable selection and adjustment according to the specific situation to ensure the safety and efficiency of the processing process. Through scientific processing methods and fine process control, the processing quality of precision steel pipes will be effectively improved to meet the needs of different industries.

Hot Blogs

Precision steel pipe processing method

Precision steel pipe is a kind of high-precision and high-quality steel pipe product, which is widely used in aerospace, automobile manufacturing, mechanical processing and other fields. The processing method of precision steel pipe plays a key role in ensuring product quality and improving production efficiency. This article will introduce several common precision steel pipe processing methods.

2023-10-03

What material is the car camshaft made of? What process material is the camshaft made

Camshaft is one of the key components of automobile engine, which is mainly composed of cam, bearing journal, journal and so on.

2023-10-10

What are the seamless steel pipe welding methods

Seamless steel pipes may need to be welded during manufacture, installation and use. The following is a list of several seamless steel pipe welding methods:

2024-01-09