Blog

What material is the car camshaft made of? What process material is the camshaft made

Summary:Camshaft is one of the key components of automobile engine, which is mainly composed of cam, bearing journal, journal and so on.

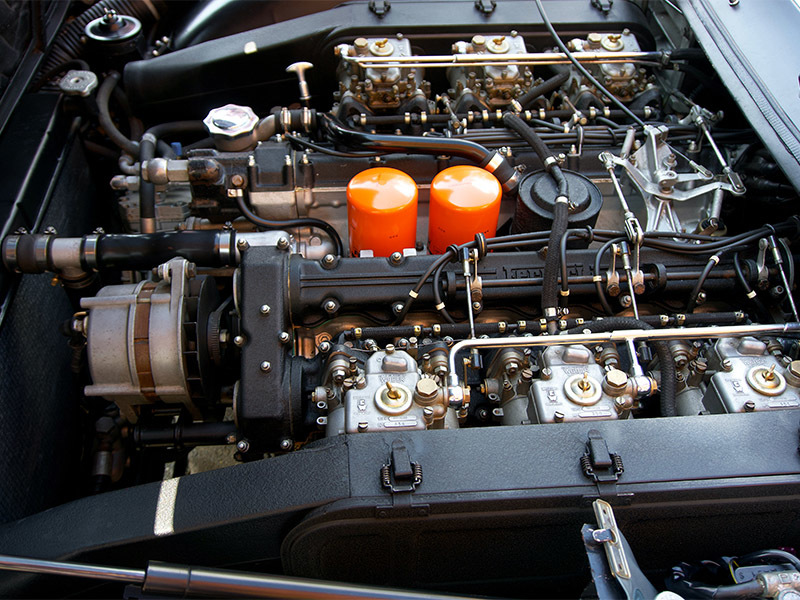

Camshaft is one of the key components of automobile engine, which is mainly composed of cam, bearing journal, journal and so on. The function of the camshaft is to control the opening and closing of the valve, and its manufacturing quality affects the engine's power index, emission index, and fuel saving index. At present, there are usually two manufacturing methods for engine camshafts in my country:

The first, chilled cast iron camshaft, mainly used for car engines;

Second, carbon steel cross wedge rolling camshaft, mainly used for truck engine. In addition, there is a combination of two or more materials assembly of the camshaft, the domestic has not yet promoted the use of large quantities.

1.Manufacturing Process of Chilled Cast Iron Camshaft

The basic performance requirements of chilled cast iron camshaft are: the chilled area of the cam surface is wear-resistant white mouth tissue, the chilled transition area is hemp mouth tissue, and the rest is pearlite gray mouth tissue. The process flow mainly includes: casting, milling, drilling, turning, grinding, polishing and cleaning, and inspection.

1. Casting

Through the casting process to obtain the internal organization and external geometric dimensions of qualified camshaft blank, casting camshaft blank as shown in Figure 2. The general method is to place the special cold iron in the sand mold, as shown in Figure 3, and then close the box, pour, and cool, so as to make the casting blank. The thickness of the cold iron and the chemical composition of the camshaft are the keys to control the internal organization of the camshaft; the shape and surface roughness of the concave surface of the cold iron determine the geometric size and accuracy of the cam.

What material is the car camshaft made of? What process material is the camshaft made?

2. Milling

The milling process mainly completes the processing of the two ends of the camshaft blank plane and takes the total length, and the high-efficiency special milling machine is generally used.

3. Drilling

Drilling process to complete the positioning center hole, oil hole and other processing, the general use of special center hole drilling machine and special CNC drilling machine, in order to ensure the quality and production efficiency.

4. Turning

Turning mainly to complete the shaft neck and other non-cooling parts of the size of the processing, the current use of CNC lathe to complete, accuracy and efficiency can be guaranteed.

5. Grinding

Grinding mainly completes the processing of the appearance of the cold cam and the appearance of the journal. At present, the special CNC grinding machine imported from Germany or Japan is used to complete the high technical requirements. The gap between domestic cam grinder and imported cam grinder is gradually narrowing.

6. Polishing and cleaning

Usually a special polishing machine is used to complete the polishing and cleaning of tiny burrs and spots on the surface of the camshaft near the finished product, and then a special cleaning machine is used to complete the cleaning of the camshaft finished product.

7. Inspection

The inspection contents include the chemical composition, metallographic structure, hardness, tensile strength, elongation, geometric size, oil hole (channel) sealing test, cleanliness test, etc. In the casting process, the chemical composition of molten iron is tested by spectral analyzer. The geometric dimension inspection of finished products mostly adopts the special detector for camshaft imported from the United States. The oil hole (channel) sealing test is completed by a special device. Figure 5 is a self-made camshaft oil hole (channel) seal test device.

What material is the car camshaft made of? What process material is the camshaft made?

Manufacturing Process of 2. Carbon Steel Cross Wedge Rolling Camshaft

The basic performance requirements of carbon steel cross wedge rolling camshaft are: the surface of the cam is a wear-resistant quenched structure, and the rest is a normalized structure. The main process flow includes: cross wedge rolling, normalizing, straightening, milling, drilling, turning, grinding, quenching, polishing and cleaning, and inspection.

1. Cross wedge rolling

The usual method is to place the heated fixed-size round steel on the wedge cross-rolling equipment equipped with a special mold and roll it to obtain the camshaft blank. The design, manufacture and maintenance of the die used are critical to the quality of cross wedge rolling camshaft blank forming. At present, the technology of finish rolling and rolling cam directly is being studied and broken through.

What material is the car camshaft made of? What process material is the camshaft made?

2. Normazing

In order to obtain good mechanical properties of carbon steel cross wedge rolling camshafts, the blanks should be normalized or quenched and tempered. Generally used to complete the continuous furnace.

3. Straightening

Carbon steel camshaft in the cross wedge rolling, normalizing and subsequent metal cutting process, due to easy bending or distortion, in the whole process needs 2~3 times straightening. At present, the domestic multi-point numerical control straightening machine should be the choice to complete the straightening task of carbon steel camshaft.

4. Milling

In addition to completing the machining of the two ends of the camshaft blank plane and taking the total length, the more important and heavy task is to mill the cam from the round wheel. Cam milling requires a special cam milling machine.

5. Drilling

The drilling process generally uses a special center hole drilling machine to complete the processing of the center hole at both ends of the camshaft, and uses a special CNC drilling machine to complete the processing of the oil hole (channel).

6. Turning

At present, many CNC lathes are used to complete the processing of carbon steel camshaft journal, bearing journal and both sides of the cam.

7. Grinding

Grinding mainly completes the processing of cam and journal appearance, generally after rough grinding (before quenching) and fine grinding (after quenching).

8. Quenching

The parts of the carbon steel camshaft that require wear resistance, such as the bearing journals and cams, must be induction hardened to obtain an effective hardened layer and surface hardness after the rough grinding process. General use of domestic special CNC medium frequency quenching machine can be completed.

9. Inspection

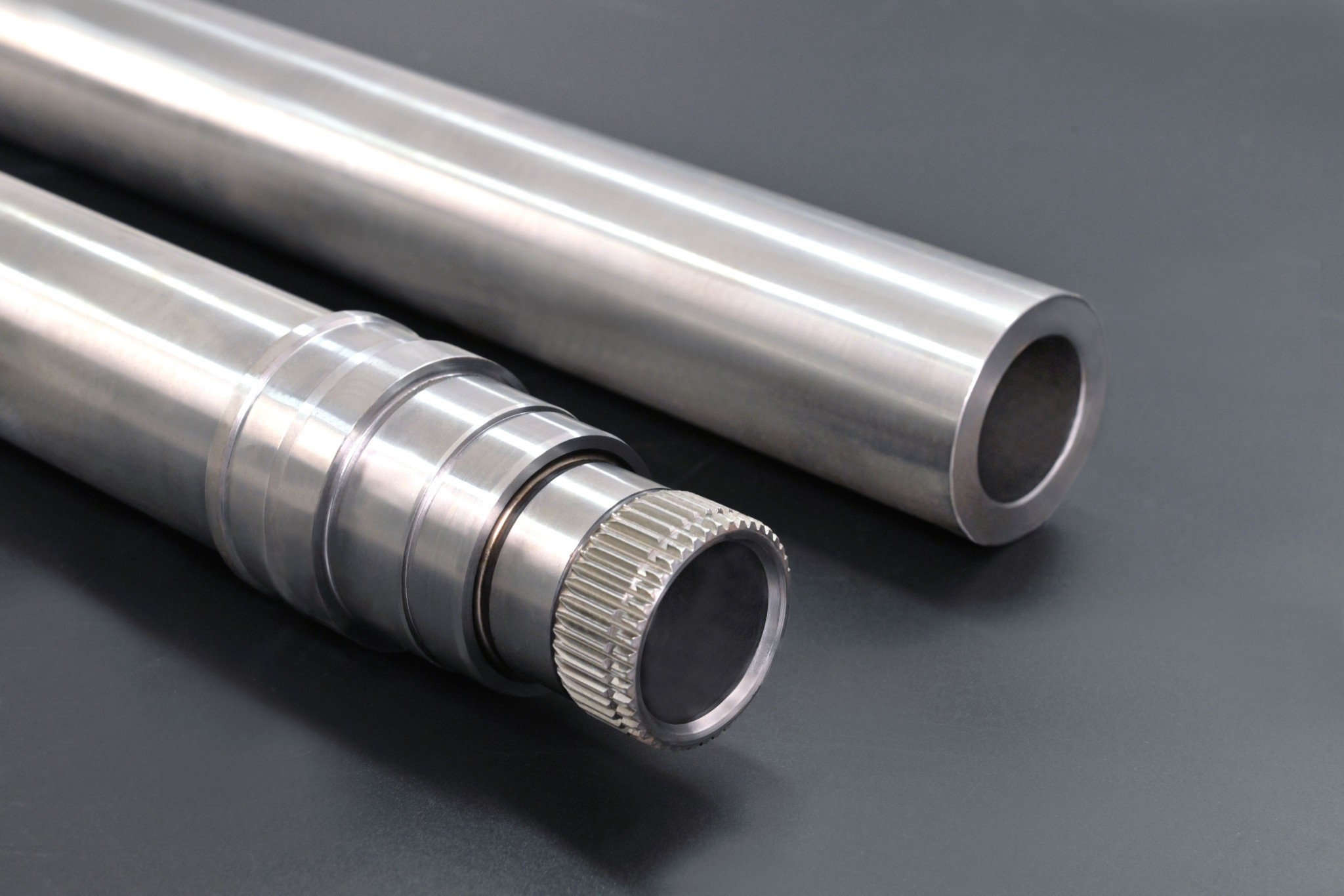

The inspection contents include the chemical composition, metallographic structure, hardness, tensile strength, elongation, geometric size and cleanliness test of the product. Figure 7 is a comprehensive detector for camshafts made in the United States. Features and applications of combined assembled camshafts Compared with integrated camshafts such as chilled cast iron camshafts and carbon steel cross wedge rolled camshafts, the advantage is that different properties can be purposefully selected at different positions of the same camshaft Material. The cam and bearing journal can generally be made by forging, cold casting or powder metallurgy. The journal is usually cold drawn steel pipe, and then the cam, bearing journal and journal are assembled together. Figure 8 shows the assembled camshaft sample.

What material is the car camshaft made of? What process material is the camshaft made?

At present, the combination of assembly camshaft connection technology in China's universities and research institutions to study more successful internal high-pressure rise connection method, mechanical over-surplus connection method. The domestic technology manufacturing assembly camshaft will soon enter the industrialization stage in China, and its popularization and application will promote the progress of engine technology.

What material is the car camshaft made of? What process material is the camshaft made?

Summary: With the rapid development of my country's automobile industry, professional manufacturers of engine camshafts have introduced, digested, and absorbed international advanced manufacturing technology and equipment, widely adopted domestic CNC automation technology, and continuously explored and innovated, effectively improving my country's engine camshafts. Manufacturing level. Of course, if our country wants to realize the progress from a big automobile country to a powerful automobile country, the manufacturing level of the camshaft, which is a key component of the engine camshaft, still needs to be improved.

Hot Blogs

Precision steel pipe processing method

Precision steel pipe is a kind of high-precision and high-quality steel pipe product, which is widely used in aerospace, automobile manufacturing, mechanical processing and other fields. The processing method of precision steel pipe plays a key role in ensuring product quality and improving production efficiency. This article will introduce several common precision steel pipe processing methods.

2023-10-03

What material is the car camshaft made of? What process material is the camshaft made

Camshaft is one of the key components of automobile engine, which is mainly composed of cam, bearing journal, journal and so on.

2023-10-10

What are the seamless steel pipe welding methods

Seamless steel pipes may need to be welded during manufacture, installation and use. The following is a list of several seamless steel pipe welding methods:

2024-01-09