Blog

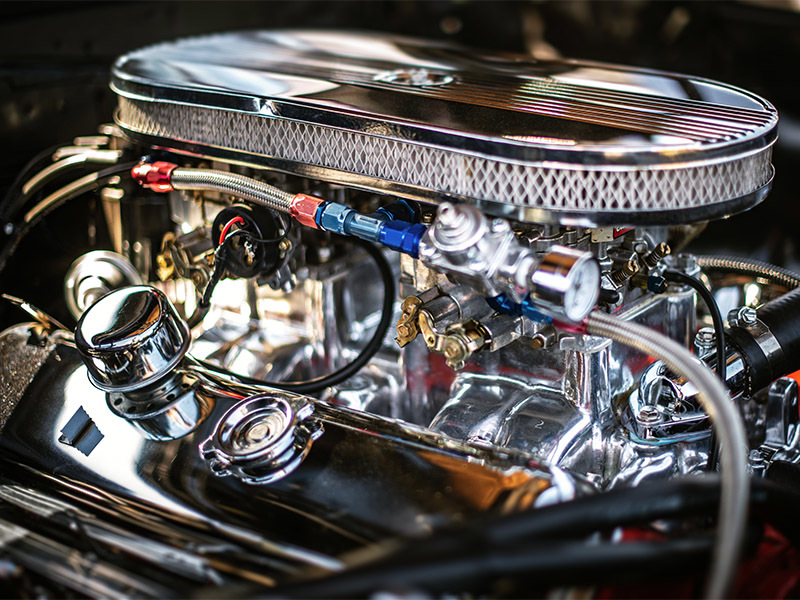

How to maintain the steering gear? Teach yourself to maintain the steering gear!

Summary:The steering gear is an important part of the car driving system. It has a significant impact on driving safety and has been valued by many car owners.

The steering gear is an important part of the car driving system. It has a significant impact on driving safety and has been valued by many car owners. However, with the increase of use time, the steering gear will also have a series of problems, such as abnormal noise, heavy weight, slow wear and return, etc., so we can only choose to replace the steering gear, and the resulting high maintenance costs are indeed a headache. Today, the editor will teach you how to maintain the steering gear by yourself.

30 seconds to read the full text of the focus:

1. Before maintaining the steering gear, a special tool needs to be designed to remove the fixing bolts.

2. First remove the dust cover, clean and lubricate the steering rod ball head.

3. Lubricate the inside of the steering gear to effectively reduce the problem of heavy steering and backlash.

4. proper adjustment of plunger tightness can effectively reduce abnormal steering noise.

Common fixing phenomenon of 1. steering gear

1. Abnormal sound: Reason: There is a gap in the wear of the steering gear rack or the wear of the ball head

2. Heavy: Reason: Lack of lubrication of steering rack

3. Slow steering return: reason: lack of lubrication of steering rack or too tight adjusting bolt

2. Maintenance Procedure

1. Lubrication of steering rod ball joint

As the use time increases, the grease of the steering rod ball joint will gradually dry out, thereby reducing the lubrication ability, which also requires us to clean and lubricate the steering rod ball joint. It is recommended to maintain it every 5 years or 50000 kilometers.

For the steering rod ball joint, the inner ball joint can be cleaned and lubricated. However, due to the disposable dust cover on the outer ball head, we cannot remove, clean and lubricate it. Therefore, we should avoid spraying detergent on the outer ball head.

2. Lubrication of steering rack

The rack steering gear realizes left and right steering through the gear transmission between the worm and the rack. Therefore, once the rack lacks lubrication, problems such as increased wear and heavy steering will occur. Therefore, after removing the left and right dust covers, we will rotate the worm left and right, and then evenly apply grease on the rack

3. Internal lubrication of the steering gear

At the rear of the steering gear, we will see the adjusting bolt shown in the figure above. We will use a special tool to remove the fixing nut and bolt and take out the internal tension plunger.

4. Control the return speed of the steering gear

5. Reduce the use of rack due to the emergence of clearance

6. Reduce the abnormal noise generated by the collision between the rack and the outer wall by the spring

7. Control steering force

After removing the tensioning plunger, we can see the rack in the steering gear. Apply an appropriate amount of grease to the car, do not apply too much, too much will also affect the steering return effect. In fact, this part of the lubrication is mainly to avoid dry friction between the rack and the plunger.

There is a seal on the plunger. In addition to sealing, it also has the function of damping vibration to avoid abnormal sound between the plunger and the outer wall due to the gap during the collision. Once the sealing ring is broken and aged, it needs to be replaced.

8. Fastening method of fixing bolts

First, we will use a special tool to rotate the fixing bolt to the tightest state, and then loosen 1/4 turn. At this point, turn the worm to see if the steering is too heavy. If appropriate, after we fix the bolt position, we can use an adjustable wrench to tighten the fixing nut of the outer ring.

9. Selection of dust cover fixture

Most steering gears use disposable clamps, so we must prepare spare clamps before disassembly. One-off is the best option. But the screw buckle has better versatility

10. Inspection of rubber sleeve

After all maintenance work is completed, we will check the various rubber sleeves of the steering gear to see if there are cracks and aging. Timely replacement if necessary

Summary:

I believe you have learned the daily maintenance of the steering gear through the above steps. Some people will say that the steering gear involves safety and cannot be repaired, which is wrong. As long as we have hands-on ability, most steering gears can be repaired to avoid replacement. If you don't have hands-on skills, you can also ask a repair shop for help to repair the steering wheel. Have you learned?

Hot Blogs

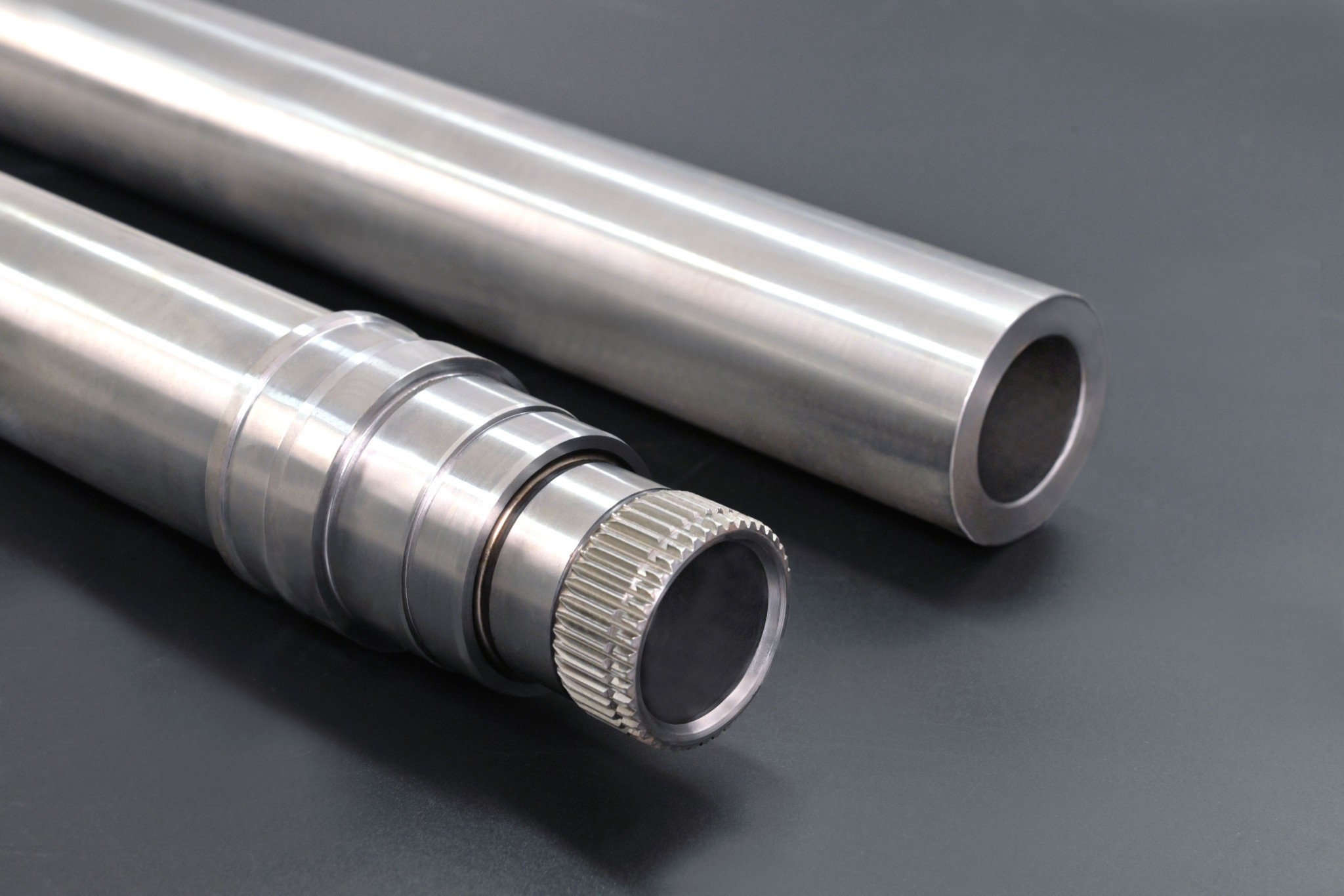

Precision steel pipe processing method

Precision steel pipe is a kind of high-precision and high-quality steel pipe product, which is widely used in aerospace, automobile manufacturing, mechanical processing and other fields. The processing method of precision steel pipe plays a key role in ensuring product quality and improving production efficiency. This article will introduce several common precision steel pipe processing methods.

2023-10-03

What material is the car camshaft made of? What process material is the camshaft made

Camshaft is one of the key components of automobile engine, which is mainly composed of cam, bearing journal, journal and so on.

2023-10-10

What are the seamless steel pipe welding methods

Seamless steel pipes may need to be welded during manufacture, installation and use. The following is a list of several seamless steel pipe welding methods:

2024-01-09