Blog

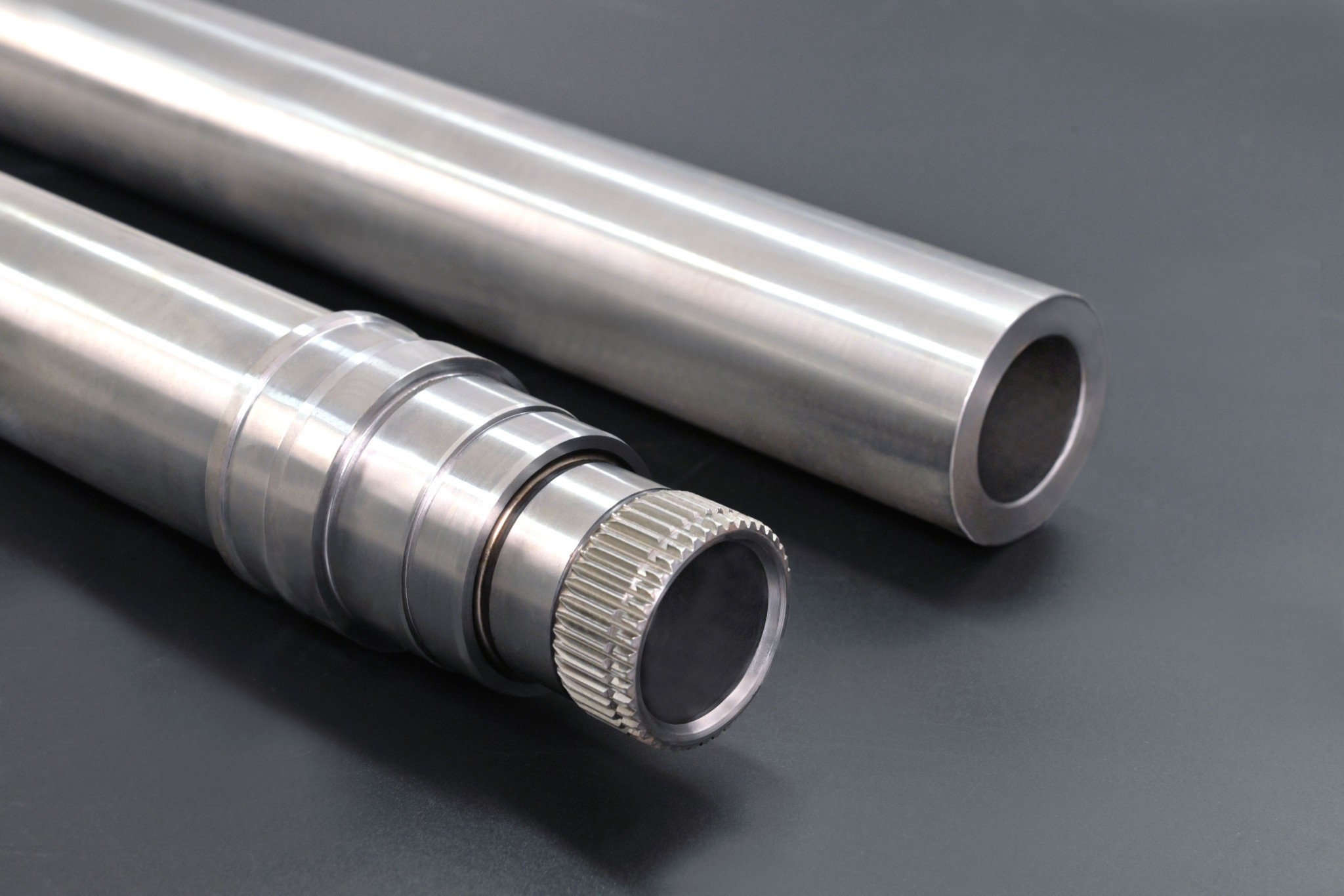

Maintenance method of precision welded pipe?

Summary:Precision welded pipe in the use of the process must pay attention to maintenance, because if the improper maintenance will cause the shortening of life, how to maintain is a problem worth considering, the following manufacturers to explain the method for you. If you are interested, you can read it.

Precision welded pipe must be used in the processPay attention to maintenanceBecause if the improper maintenance will cause the shortening of life, how to maintain is a problem worth considering, the following manufacturers for you to explain the method. If you are interested, you can read it.

Precision welded pipes are often used in construction, automobiles, decoration and other fields, especially stainless steel welded pipes used as outdoor railings, which require high surface finish. However, due to the large flow of people outdoors, the surface of the precision welded pipe that has been used for a long time will have many fingerprints and is not smooth. What you need to know is that general scrubbing does not remove surface problems very well. Cleaning is not simple. Just scrub with a rag or add a little detergent to clean. This is also a more detailed work. It is recommended to prepare two soft and delicate towels, wet wipes can also be. Or choose to buy stainless steel cleaner. Here we suggest that we must pay attention to the purchase of regular manufacturers of products. Then, the surface of the precision welded pipe can be wiped clean with a soft towel, and then wiped repeatedly with a slightly watery towel until there is no obvious mark on the surface. Then pour the cleaning agent into the towel to make it evenly dispersed, and then wipe back and forth on the surface of the precision welded pipe. Clean the surface of the precision welded pipe with a clean wet towel to remove the dirt of the cleaning agent.

If the precision welded pipe is damaged, it should be polished, especially the damage caused by scratch, splash and cutting slag caused by contact with carbon steel parts, which must be carefully and thoroughly cleaned and polished. Polishing with a suitable polishing tool requires uniform processing to avoid over-polishing and re-scratching. Before pickling and passivation, the welded pipe must be cleaned of oil, oxide skin, dust and other debris according to the welded pipe process. Another important point is that for different microbeads, different process parameters must be selected according to different processing requirements to avoid overspray. Pickling passivation of precision welded pipe must be strictly in accordance with process requirements. Or in the pickling passivation in strict accordance with the process of neutralization, rinsing, drying, in order to completely remove the residual acid. After the surface treatment of precision welded pipe is completed, it should be well protected to avoid personnel contact and secondary pollution of oil, dust and other debris.

The above content is the maintenance method of precision welded pipe that Xiaobian told friends. Other knowledge points about precision welded pipe will continue to be updated in the next period. Remember to pay more attention to the website so as not to miss the wonderful content.

Hot Blogs

Precision steel pipe processing method

Precision steel pipe is a kind of high-precision and high-quality steel pipe product, which is widely used in aerospace, automobile manufacturing, mechanical processing and other fields. The processing method of precision steel pipe plays a key role in ensuring product quality and improving production efficiency. This article will introduce several common precision steel pipe processing methods.

2023-10-03

What material is the car camshaft made of? What process material is the camshaft made

Camshaft is one of the key components of automobile engine, which is mainly composed of cam, bearing journal, journal and so on.

2023-10-10

What are the seamless steel pipe welding methods

Seamless steel pipes may need to be welded during manufacture, installation and use. The following is a list of several seamless steel pipe welding methods:

2024-01-09