Blog

Precision welded pipe processing technology and manufacturing process steps

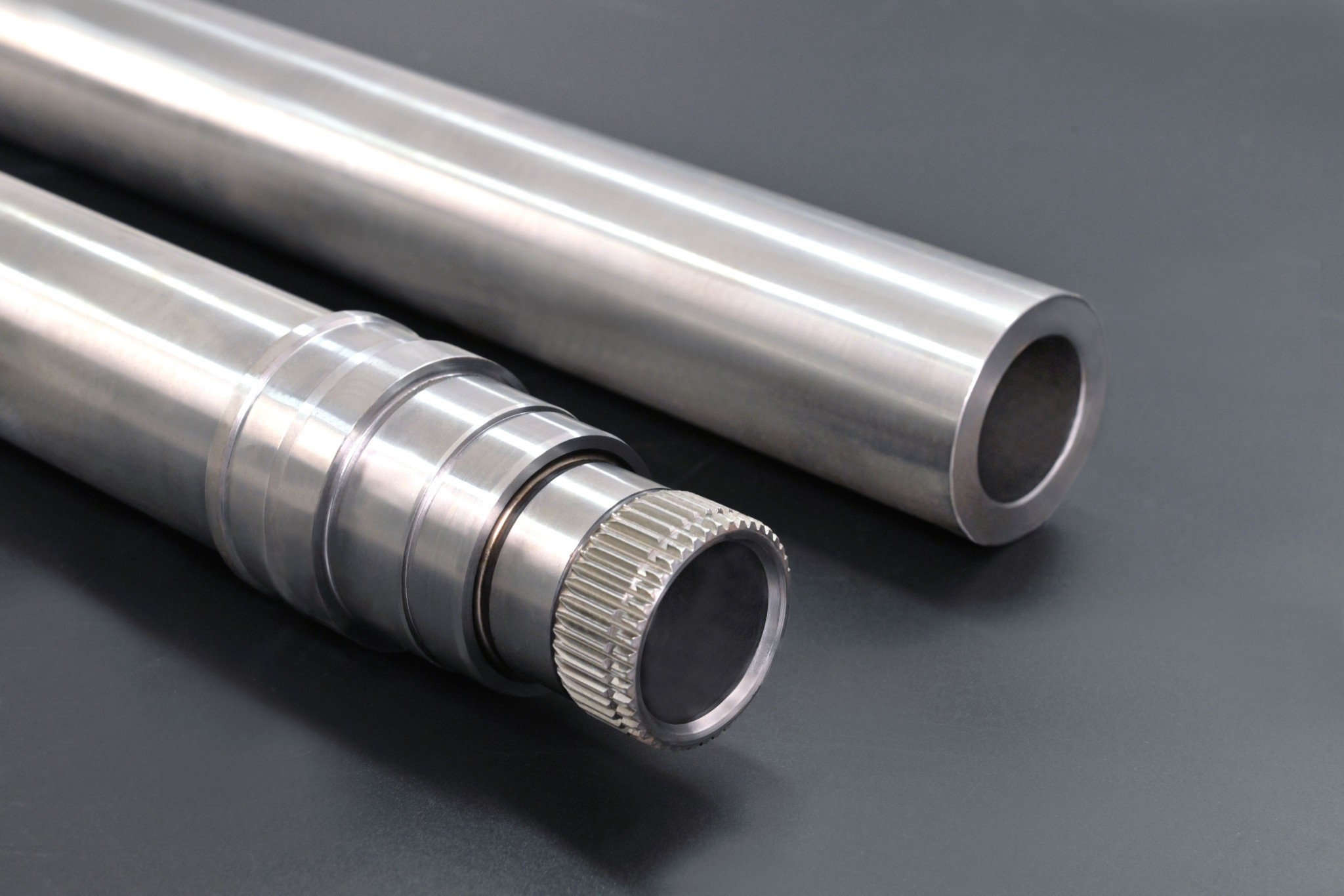

Summary:The production process of ordinary precision welded pipe can be divided into cold drawing and hot rolling. The production process of cold-rolled precision tubes is usually more complicated than that of hot-rolled tubes.

The production process of ordinary precision welded pipe can be dividedcold drawnandhot rollingTwo kinds. The production process of cold-rolled precision tubes is usually more complicated than that of hot-rolled tubes. Test, if the surface does not respond to cracks, the round tube is cut with a cutting machine and cut into blanks with a length of about one meter. Then enter the annealing process. Annealing should be done with acid liquid pickling. When pickling, pay attention to whether the surface bubbles. If there is a lot of foaming, it means that the quality of the steel pipe does not meet the response standard. The appearance of the cold-rolled precision tube is shorter than that of the hot-rolled precision tube. The wall thickness of cold-rolled precision welded pipe is usually smaller than that of hot-rolled precision pipe, but the surface looks brighter than that of thick-walled precision welded pipe. The surface does not have too much roughness and caliber. Not too many failures. The delivery status of hot-rolled precision pipes is usually the delivery status after heat treatment. After quality inspection, the staff strictly selected hot-rolled precision welded pipe by hand. After quality inspection, oil on the surface, then multiple cold drawing tests, and perforation tests after hot rolling treatment. If the diameter of the perforation is too large, it needs to be straightened and straightened. After straightening, it is transferred to the flaw detector by the conveyor belt for flaw detection experiments. After that, paste the label, arrange the specifications, and then place it in the warehouse.

Round tube blank hot rolling → heating → perforating → three-roll cross rolling, continuous rolling or extruding → removing the tube → sizing (or reducing the diameter) → cooling → straightening → hydraulic test (or flaw detection) → marking → storage accuracy The tube is made of steel ingot or solid tube blank through perforation, and then it is hot rolled, cold rolled or cold plucked. The specifications of precision welded pipe are expressed in outer diameter * wall thickness (mm). Precision welded pipe is divided into hot rolled and cold rolled precision pipe.

Hot-rolled precision welded pipes are divided into ordinary steel pipes, medium and low pressure boiler steel pipes, high pressure boiler steel pipes, alloy steel pipes, stainless steel pipes, petroleum cracking pipes, geological steel pipes and other steel pipes. Cold-rolled (turntable) precision pipe is divided into ordinary steel pipe, medium and low pressure boiler steel pipe, high pressure boiler steel pipe, alloy steel pipe, stainless steel pipe, petroleum cracking pipe and other steel pipe, but also includes carbon steel pipe thin-walled steel pipe, alloy thin-walled steel pipe, rusty thin-walled steel pipe and special-shaped steel pipe. The outer diameter of hot-rolled seamless pipe is usually greater than 32mm, the wall thickness is 2.5-200mm, the diameter of cold-rolled precision welded pipe can be 6mm, the wall thickness can be 0.25mm, the thin-walled pipe can be 5mm, and the wall thickness is less than 0.25mm. It has higher dimensional accuracy than hot rolling.

Hot Blogs

Precision steel pipe processing method

Precision steel pipe is a kind of high-precision and high-quality steel pipe product, which is widely used in aerospace, automobile manufacturing, mechanical processing and other fields. The processing method of precision steel pipe plays a key role in ensuring product quality and improving production efficiency. This article will introduce several common precision steel pipe processing methods.

2023-10-03

What material is the car camshaft made of? What process material is the camshaft made

Camshaft is one of the key components of automobile engine, which is mainly composed of cam, bearing journal, journal and so on.

2023-10-10

What are the seamless steel pipe welding methods

Seamless steel pipes may need to be welded during manufacture, installation and use. The following is a list of several seamless steel pipe welding methods:

2024-01-09